Do you have a process that can't easily be measured with probes or sensors, but you can view it from a camera? Have you ever thought, "I know what's supposed to happen, but can I 'see' it?"

Using computer vision automation, now 'seeing' is all you need to do.

Define the metrics you're targeting and decide how you want your system to look. Taber will fill in the rest allowing for an effective and streamlined process.

Key Features of Taber's Computer Vision Automation

Real-Time Monitoring

With our computer vision solution, monitor your entire production line in real-time. Identify bottlenecks, detect defects, and ensure optimal performance with instantaneous feedback.

Quality Assurance

Say goodbye to costly errors and defects. Our system employs high-precision image recognition to inspect products with unparalleled accuracy, guaranteeing top-notch quality in every unit produced.

Predictive Maintenance

Eliminate costly downtime by predicting potential equipment failures before they occur. Our system analyzes equipment behavior, detects anomalies, and recommends maintenance actions to keep your operations running smoothly.

Workflow Optimization

Streamline your production processes by identifying inefficiencies and optimizing workflow. What sets us apart is our system’s adaptability—ease of customization to unique process conditions ensures that your specific process nuances are accounted for, delivering optimal efficiency in every scenario.

Safety Compliance

Prioritize the well-being of your workforce with enhanced safety measures. Our system can detect unsafe conditions, monitor employee compliance with safety protocols, and generate alerts to prevent accidents.

The opportunities for applying computer vision to improve industrial control are limitless.

Examples of how Taber can help you.

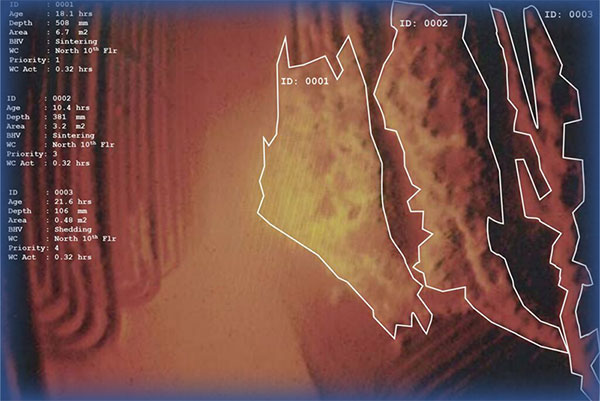

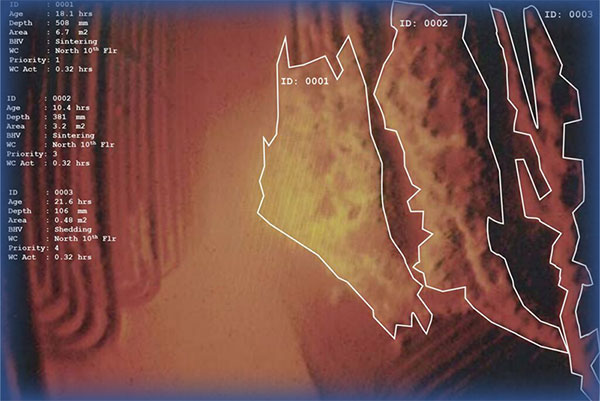

- Intelligent sootblowing in response to actual slag formation rates and profiles observed within the boiler

- Product manufacturing automatic feedstock placement and flowrate adjustments based upon visual analysis of product and batch characteristics

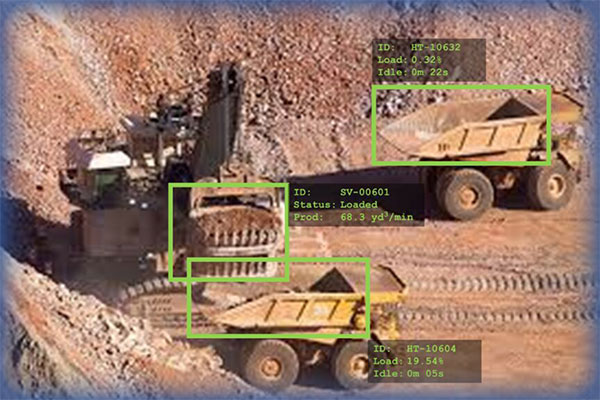

- Mining, construction, and factory floor equipment and asset health monitoring and production tracking

- Warehousing logistics and inventory monitoring and prediction

- Remote diagnostics and closed-loop system response within SCADA systems

![]()

In the relentless pursuit of industrial excellence, don’t just keep pace — set the standard. Our computer vision solution transforms your industrial line into a beacon of efficiency, precision, and innovation. Embrace the future today and redefine what’s possible in industrial process control.

Deploying advanced automation grounded in computer-vision methods can realize multiple advantages for your process.

Increased Efficiency

Boost your production efficiency by minimizing downtime, reducing defects, and optimizing workflows. Our computer vision solution empowers you to achieve more with less.

Cost Savings

Experience significant cost savings through reduced defects, preventive maintenance, and optimized resource allocation. The initial investment in our technology pays off quickly through improved overall operational efficiency.

Scalability

Our solution is designed to grow with your business. Whether you operate a small factory or a large industrial complex, our computer vision system scales to meet your evolving needs.

Competitive Edge

Stay ahead of the competition by adopting cutting-edge technology. Showcase your commitment to innovation and quality, attracting partners and customers who prioritize excellence.

optimize the complex, automate the mundane

talk to an expert