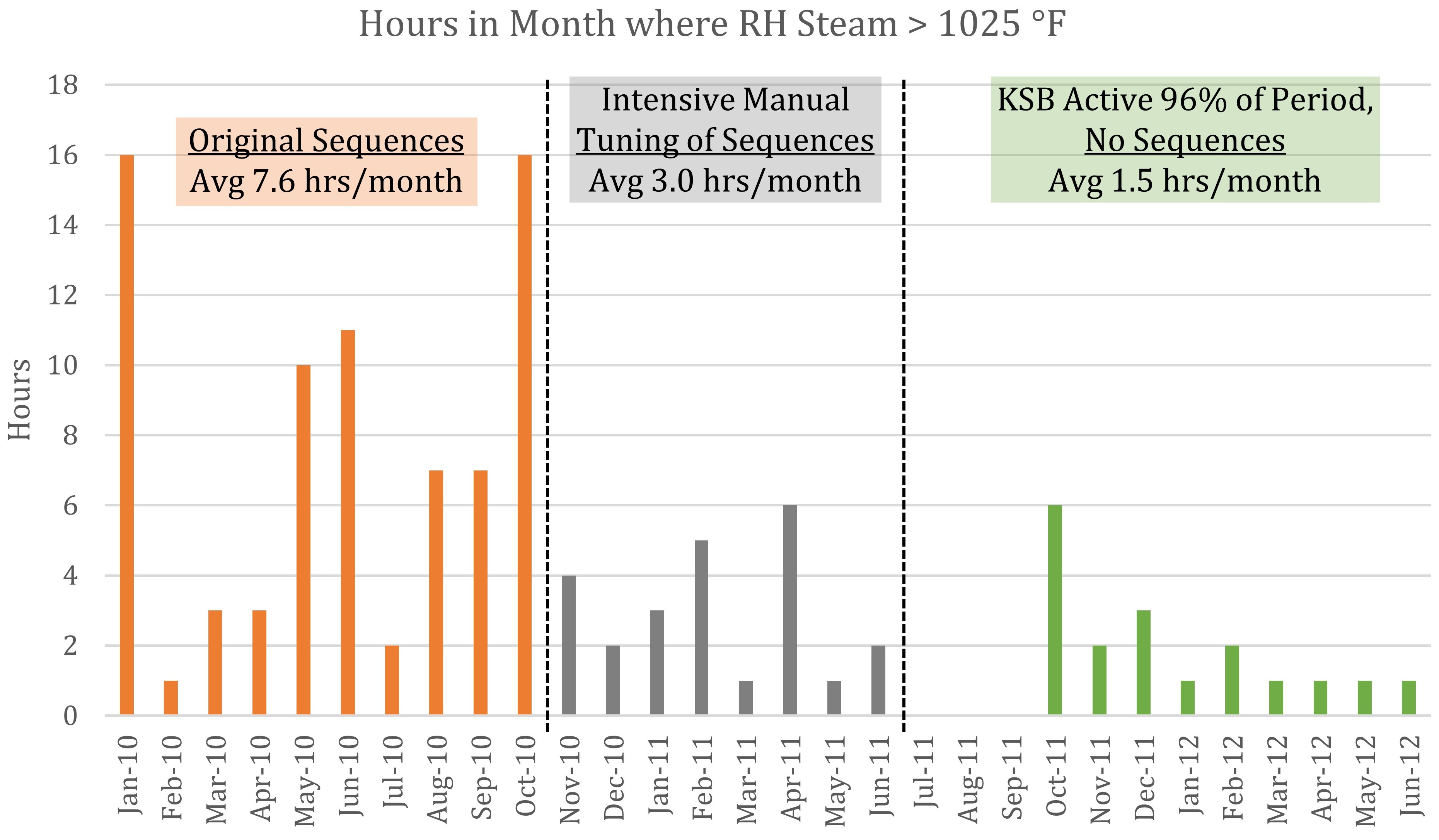

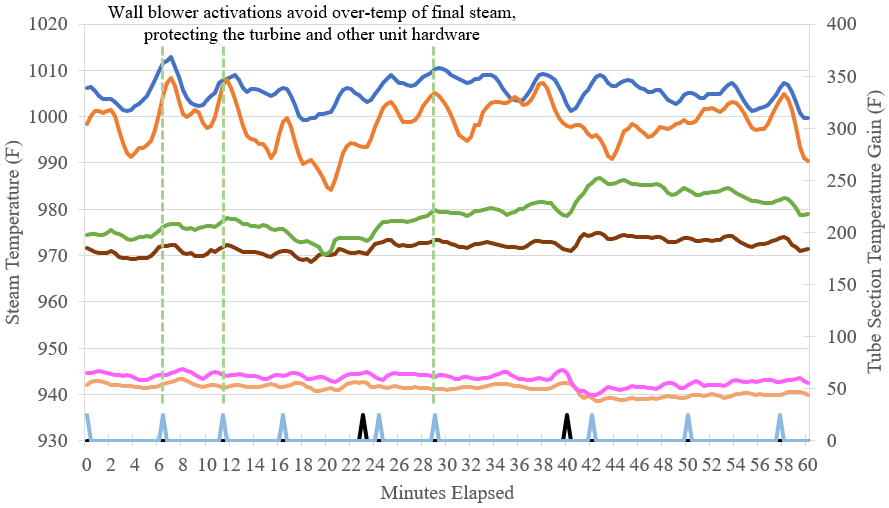

Implement Intelligent Sootblowing (ISB) for improved coal-fired power plant operation and unit cleanliness. Our Knowledge-Based SootBlowing (KSB) application can utilize any existing hardware (e.g., flux sensors, thermocouples, furnace cameras, etc.) or include hardware installation to maximize the efficiency and stability of your furnace through optimal boiler cleanliness. Watch a system cycle below!

![]()

Sootblowing Optimization

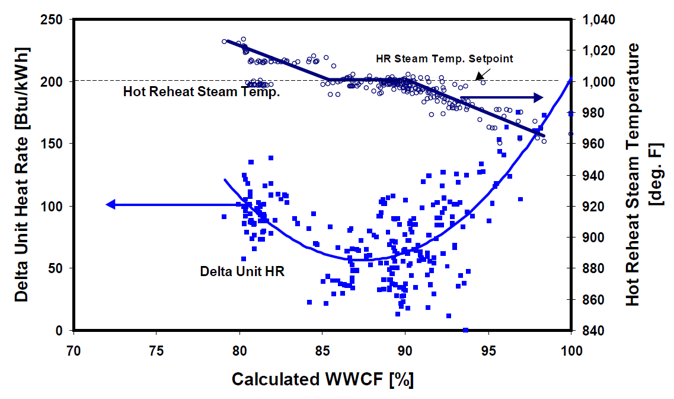

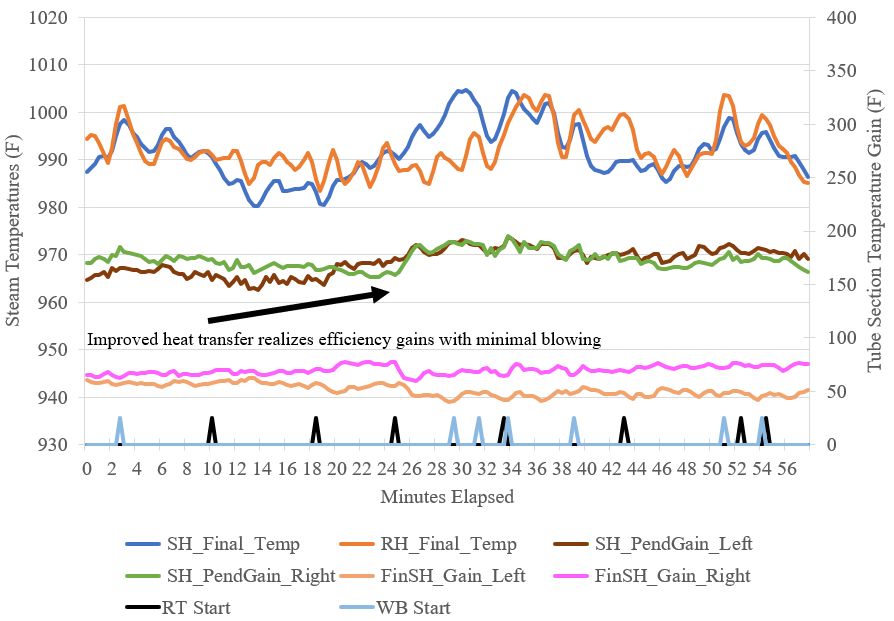

- Greater Efficiency Upgrade your time based sequencing system with an effective and easy to use system that continually monitors plant conditions and evaluates which blower will offer the maximum benefit. Operating blowers only as conditions dictate avoids unnecessary sootblowing activities while improving the stability of key operating parameters. This reduces time spent by operations ‘cleaning up’ the unit and permits greater availability of blowers for dual header systems. Overall, this realizes improved heat rate and less stress on heat transfer surfaces, as well as improved unit operating consistency.

- High Availability Within KSB the focus is on cleaning to maintain temperatures, pressures, and temperature & pressure deltas across the furnace, along with other key control signals. This results in a high availability system for continually evaluating priorities versus current conditions.

- Easy Customization, Low Maintenance

Taber’s KSB application is configured through a series of user tuning screens and an easy to use Graphical Programming Environment (GPE). No programming is required and there are no ‘black-box’ components. The end-user operators and engineers can easily modify the system over time to meet changing objectives and conditions, or simply make temporary adjustments in response to short-duration conditions or circumstances.

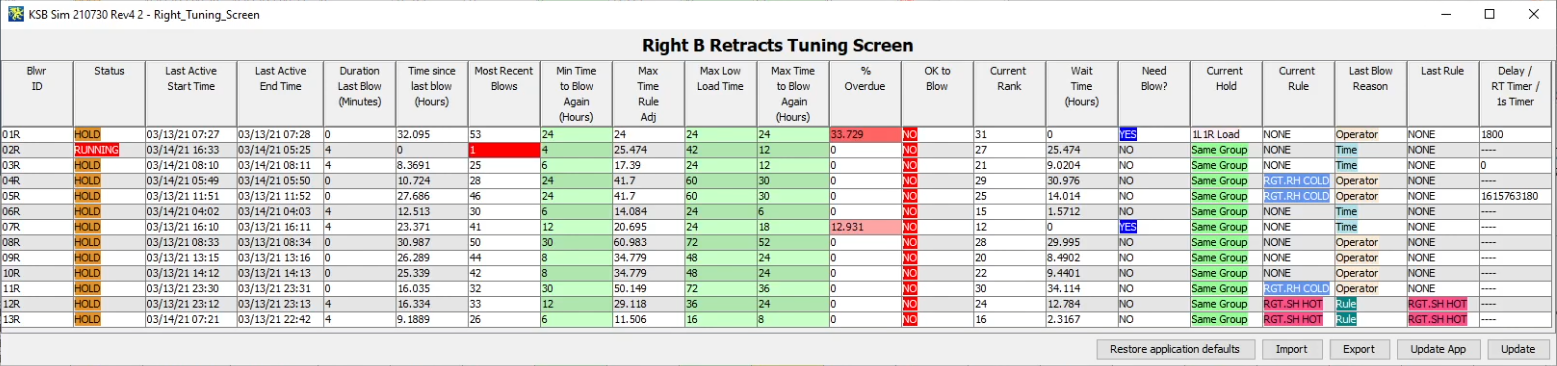

Below is a sample tuning screen. Columns in green are areas an engineer uses to tune the system. Status reflects blower state and additional alarms created by KSB for detecting blowers that have failed to activate or failed to run a sufficient period of time. The current history of activations and ranking of upcoming activations within the blower group are indicated, and the reasons for accelerated run time (rules) or paused activation (holds) are shown. The reason for the last blower activation is also displayed.

- Quick & Cost Effective Installation KSB is designed to provide the maximum benefit without requiring expensive new equipment, sensors or time consuming calculations. The system quickly integrates with existing PLC and DCS systems. In many cases, the operator can keep their existing displays and functionality.

- Rapid Expansion Capability When enhanced capabilites are the goal, KSB projects are readily combined with advanced instrumentation and hardware (e.g., thermal cameras, laser measurement systems, etc.) to achieve unparalleled performance within a fully integrated, seamless system.

System Overview

The Taber KSB system is configured to fit your operating needs. Once configured, the KSB system will perform an evaluation of each of the blowers every few seconds against the desired control values. When a sootblowing operation is permitted, the priority of every blower will be calculated based on the user-set tunable parameters. These parameters are dynamic (e.g. RH blowers may get their ranking factor accelerated relative to economizer blowers when final RH steam temperature are low). These live system evaluations take place in well under 1 second, meaning that the system can be immediately responsive as necessary to changing unit conditions (e.g. steam temperature spikes that need a quick blower activation to mitigate).

All parameters are available through tuning screens, and prioritization logic is viewable and changeable through the Taber application GPE. With this user-friendly setup, tuning is available to a wider set of engineers and operators and logic changes are accessible to the end-user without supplier intervention. With the Taber KSB system, sootblowing operations now activate based on key unit parameters and constraints, resulting in a break from ‘blind’ time-based blowing.

The Taber KSB system has the ability to add operator features, separate from the PLC’s. For example, a prohibit may be created to prevent blowing on one side of the furnace due to elevated temperatures, which allows some blowers to remain active while conditions improve on the opposite side blowers. This ability to keep some blowers in service avoids the need to do ‘catch-up’ manual blowing.

Using the Taber KSB system frees operators from time consuming sootblowing operations, while standardizing the method for determining blower activation. The system can also be configured to automatically respond to changes in fuel, long periods at full loads and other characteristics.

![]()

KSB deployments are always specifically tuned to the needs of the unit they are applied to. This often results in two general configurations, the “high-slagging” system and the “high-temperature” system. Each is easily managed using the combination of KSB rules, holds, and data analytics.

'Slagging' System Performance Feedback

“The KSB system works very well. As you know, our previous system was sequence-based. KSB is a huge improvement over our previous system and it is maintaining the cleanliness very well. We’ve had a few short boiler outages on our unit where KSB is installed. I make it a point to check the reheater for slag when the unit is off. I haven’t seen any issues. The operators ask me, “When are we going to roll KSB out to the rest of the units?” My standard answer is usually “not soon enough”. Before KSB, I was walking the unit down easily once a week, sometimes more. Usually we asked Operations to blow certain lances, which required verification and a physical check to make sure it achieved the level of cleanliness that we wanted. Sometimes I would change sequences to get the boiler clean…which usually required a week or so to tweak the sequence, document the changes and verifications. Before KSB, boiler cleanliness consumed 30% of my day. Now with KSB, I don’t do any of the tweaking anymore. KSB does it for us. As pleased as I am with KSB, what amazed me most was how smoothly and effectively KSB was rolled out. It was almost seamless and very professionally done. I’ve never been involved, at any place I’ve ever worked, where a change of this magnitude was rolled out so smoothly and seamlessly across multiple shifts.” - Ben Hanneken, Career Engineer, Labadie Energy Center

'High-Temperature' System Performance Feedback

“KSB enabled us to break away from sequence blowing [and] got rid of 25+ operator-based sequences that were overkill. Blowers run more as needed now, with roughly 20-30% aux steam savings. We’ve been able to tune KSB rules and holds on blowers such that our units are as efficient and as clean as needed for baseload, as well as being [as] inefficient and dirty as needed to keep exit temps up at low loads for best ESP and SCR operation, the latter of which has made for better flexibility and turndown.” - Doug Sturm, Sr Engineer, CGS Operations

![]()

optimize the complex, automate the mundane

talk to an expert