Turbine and generator efficiency affects nearly all types of power generation methods, from nuclear to geothermal to wind. Many of the larger generators utilized in power generation employ hydrogen within the casing to provide cooling as well as reduce rotor drag. Control over the hydrogen within the generator presents an excellent opportunity for site efficiency improvement and lowering overall operating costs.

Opportunity - Dynamic Pressure Control

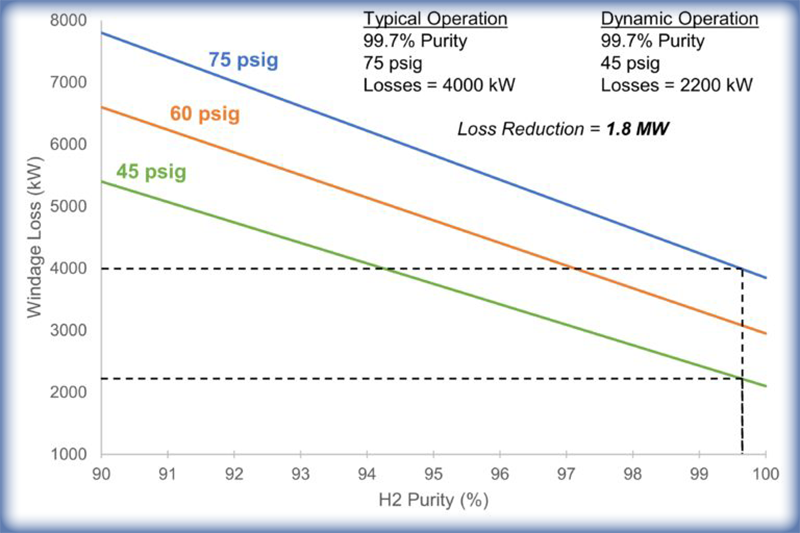

Hydrogen pressure within the generator casing can be dynamically controlled using intelligent systems and expert knowledge to provide a significant improvement to operating costs and efficiency. The balance between low and high relative pressure is based upon the amount of cooling load necessary. Intelligence is important to pre-emptive adapt to changing load conditions and maintain adequate cooling at all times, thereby improving generator temperature consistency and prolonging material life. During operation where less cooling is needed, the hydrogen pressure can be allowed to decrease, which further reduces drag on the generator rotor, increasing efficiency, while also avoiding electrical load on compressors and wear and tear on generator seals, decreasing costs.

![]()

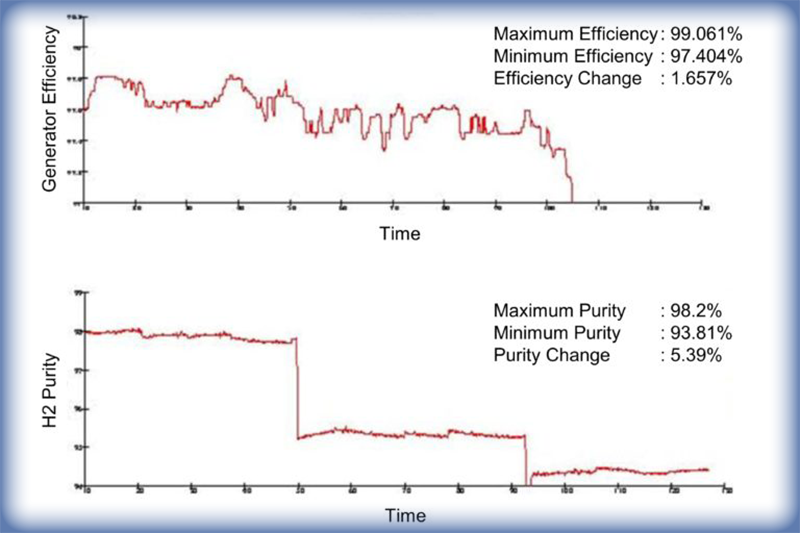

Further, the process of decreasing pressure periodically assists with purging and helping to maintain a higher H2 purity. The effect of purity on generator losses is pronounced, and keeping this as high as possible is desired. Measurements on an operational generator confirm the effect of H2 purity on generator efficiency.