Every site and process is unique, but we're all pushing to be the best possible. Whether that's efficiency, product quality, flexibility, reliablity, cost-effectiveness, or any other measure of "best", Taber has the resources to be there and support you to make it reality.

There's no cost or commitment to explore working with Taber, simply reach out to see what we could do for you. When appropriate, Taber will perform a no-cost site visit to review and assess the ways your system could benefit.

![]()

Taber International’s partner approach is fully client-centric, focused entirely on addressing our client's major process & business goals while incorporating day-to-day problems & tasks within the improvement framework.

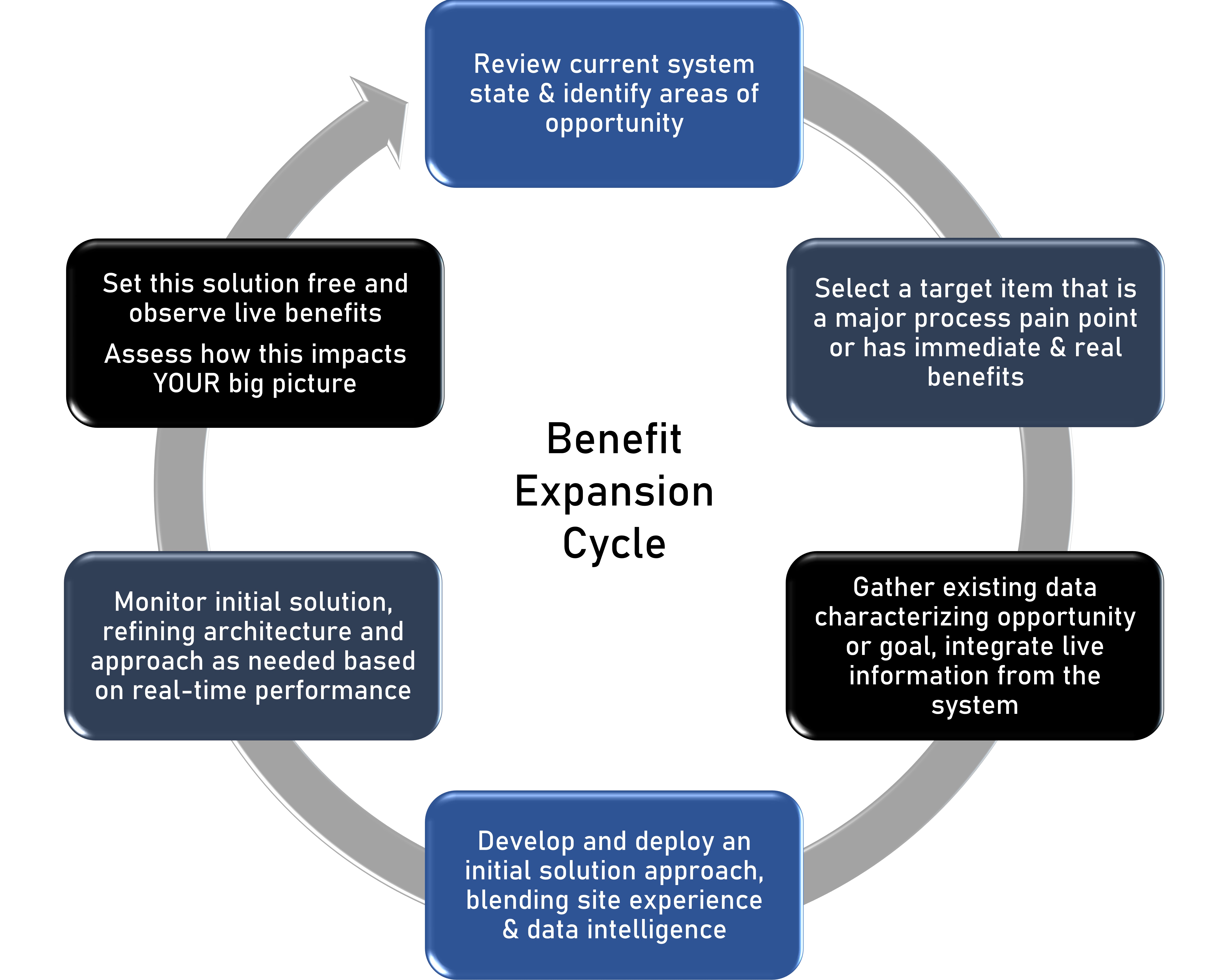

From day one, Taber works with clients to progress through the "Benefit Expansion Cycle", identifing process improvement opportunities and making the changes to systems and practices that will realize benefits. As one benefit is achieved, the cycle continues to include more areas and more benefits, creaing a compounding effect.

What do those we work with say?

Effective & Seamless Rollout

"As pleased as I am with KSB, what amazed me most was how smoothly and effectively KSB was rolled out. It was almost seamless and very professionally done. I’ve never been involved, at any place I’ve ever worked, where a change of this magnitude was rolled out so smoothly and seamlessly across multiple shifts.” - Ben Hanneken, Career Engineer, Labadie Energy Center

Above & Beyond

[Our Taber project engineer] Keane deserves to be recognized for the excellent work he has done on our project. He has gone above and beyond to get this project done to our liking. Everything is straight forward, easy to navigate, and looks great. I do not regret switching from [our previous provider] to Taber & Griffin.” - Operations Manager, Coal-Fired Power Plant, United States

Responsiveness & Operator Acceptance

"[We] started load cycling and low load operation back in the 2016-17-time frame. Our current load range capability is from 15% minimum MDC to 100% maximum MDC. Flexibility is our current reality and maintaining stability during load ramps takes continuous monitoring and adjustments. The inherent problems associated with load ramping and cycling (pressure swings, temperature swings, and low total air flow at lower loads) have been minimized to certain extent, by the optimizer. In our system load ramps are almost never continuous. There may be 2-3 interruptions or pauses in the total ramp. For example, an afternoon peak load ramp may be from 15% MDC to 80% MDC with a 15-minute pause at 40% and the same at 60%. At each of these pauses is where we have seen the worst pressure and temp swings. The optimizer can anticipate these excursions and utilize the sprays and/or burner tilts to minimize the effects of the event. I think one of the best indicators of this application is operator acceptance. Anyone who has worked at a power plant and has anything to do with operations knows “without operator by-in” the program will fail. Here our operators have seen positive results and are willing to work to make it better, which makes their life better. – Asst. Operations Manager, Coal-Fired Power Plant, United States

![]()